I. Test Method Outline

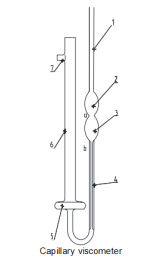

1. Fix the viscometer which is filled well with sample on the viscometer clip cover and adjust it to vertical situation.

2. Adjust the constant temperature bath to be at specified temperature, dip the viscometer into the bath to be preheated (refer to the standard for preheating time). The test temperature must be kept constant within ±0.1℃ . When fix the position, the expansion part 2 of capillary viscometer must be dipped for half part.

3. Fix the thermometer. You need make the mercury ball position near to the level of capillary middle point, and make the thermometer scale which will test temperature at 10mm above the bath. When using the fully immersed type thermometer, please refer to the required calculation formula in standard to calculate the correction number.

4. Use the rubber tube covered on capillary viscometer body 1 port to inject the sample into expansion part 3, make the sample liquid level a little higher than the marking line a, and pay attention not to make bubble or gap generated on the liquid levels of capillary and expansion part 3.

5. At this time observe the flowing condition of sample in the tube body. Start the stopwatch when liquid level exactly reach marking line a, and stop it when liquid level exactly reaches marking line b.

1 .6-tube body; 2 .3 .5-expansion part; 4-capillary; a 、b-marking lines

6. The flowing time recorded by stopwatch needs to be repeatedly tested at least four times. The difference between every flowing time and its arithmetic mean value needs to meet the following requirements: no more than ±0.5% of the mean value at testing temperature of 100-15℃; no mare than ±1.5% at 15~ -30℃; no more than ±2.5% at lower than -30℃ . Then take the arithmetic mean value of flowing time for no less than 3 times to be the average flowing time of sample.

7. Calculate:

1) Please refer to standard to carry out the sample kinematic viscosity value calculation at temperature t.

2)Please refer to standard to carry out the sample kinetic viscosity value calculation at temperature t.

II. Main Technical Parameters

Temperature control range: continuously adjustable 20℃-100℃

Temperature control precision: ±0.1℃

Input power: 2000W

Power supply: 220V±10%, 50Hz

Size: 635×380×525mm, 4 holes

III. Performance & Feature

1. The adopted constant temperature bath is round glass cylinder. The outer layer is organic glass cover to keep the temperaure.

2. Adopts the latest PID temperature control technology to control the bath temperature with temperature control accuracy ±0.1℃ .

3. Even and stable bath temperature; accurate and convenient temperature test; with good light transmission.

4. The operating interface adopts touch screen LCD, convenient for operation, with timing function to spare operation of holding stopwatch in hand.

5. The tested data is automatically processed and it calculates viscosity factor and kinematic viscosity. It can also convert viscosity index.

6. Thermal printer is equipped to freely print out calculating result.